1, monocrystalline silicon and polysilicon

Silicon is a hard brittle material, Mohs hardness of 6.5, according to the use of polysilicon, monocrystalline silicon. Monocrystalline silicon is a relatively active non-metallic element. This crystal has basically complete lattice structure and is a good semiconductor material with purity up to 99.9999%. It is mainly used for manufacturing semiconductor devices and solar cells. Monocrystalline silicon (FIG. 1A) is usually manufactured by first producing polysilicon or amorphous silicon and then growing rod-like monocrystalline silicon from the melt by either cignification or suspension zone melting.

Polycrystalline silicon (Figure 1B) is a relatively different form of elemental silicon. When molten elemental silicon is solidified under the condition of supercooling, silicon atoms are arranged into many crystal nuclei in the form of diamond lattice. For example, these crystal nuclei grow into grains with different crystal plane , and these grains are combined to crystallized into polycrystalline silicon. Polycrystalline silicon is the direct raw material for the production of monocrystalline silicon, and it is the electronic information basic material of modern artificial intelligence, automatic control, information processing, photoelectric conversion and other semiconductor devices. It is called "the cornerstone of the microelectronics building".

2 Processing flow

The processing process of monocrystalline silicon mainly includes: truncation → rolling → cutting square → grinding → slicing → chamfering → grinding → chemical corrosion → polishing and so on. In contrast, polycrystalline silicon has no truncation and rolling steps, only after the preparation of the ingot, can be cut square and slice.

In the whole preparation process of monocrystalline silicon and polycrystalline silicon from rod (ingot) to chip, diamond tools of different uses are required to participate in the processing, and the processing accuracy is relatively high. Detailed steps, corresponding tools and indicators are shown in Table 2.

3 Introduction to diamond grinding wheel

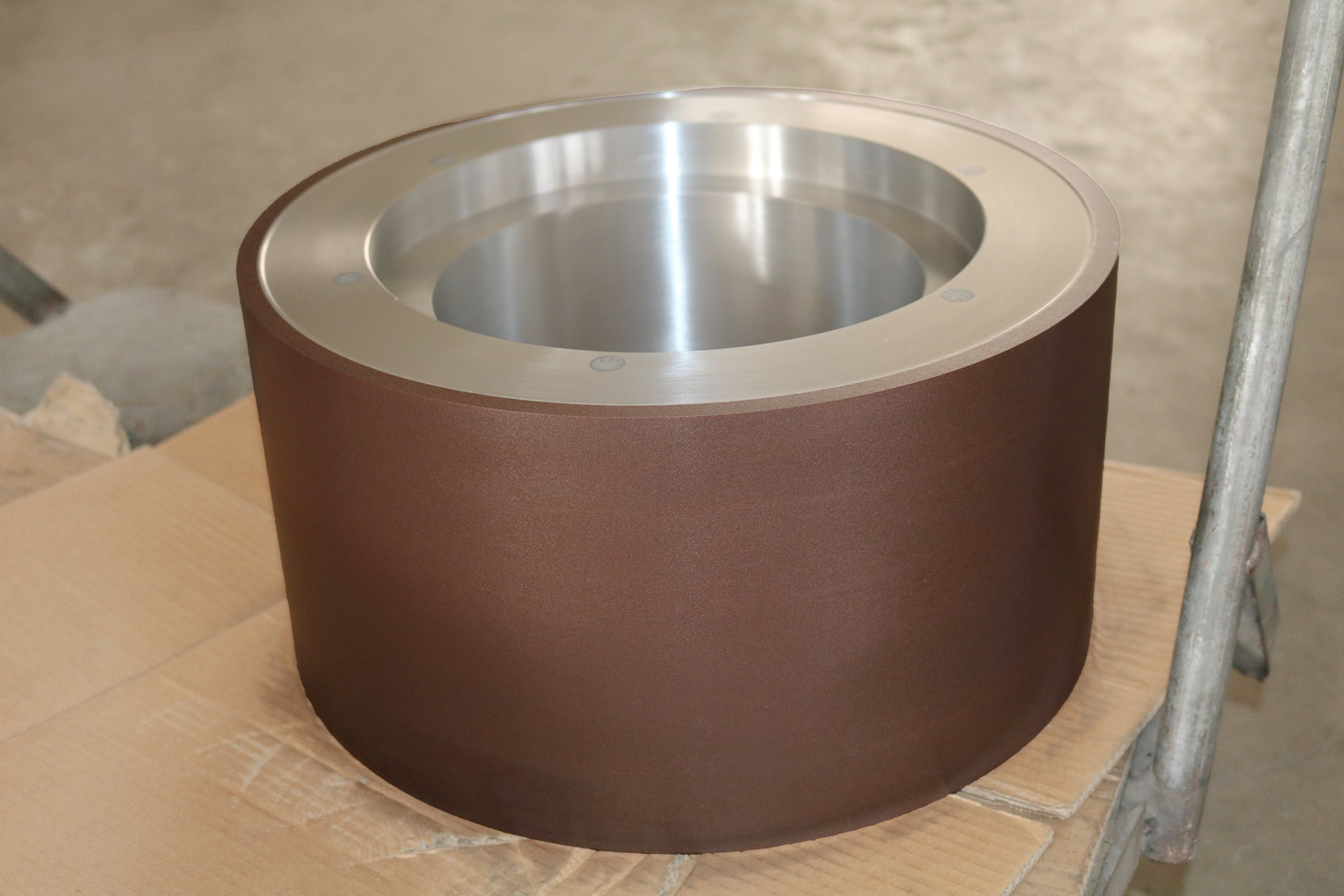

Diamond grinding wheel is widely used in the processing of hard and brittle materials such as crystal silicon and sapphire. In the photovoltaic industry, it is mainly used in monocrystalline silicon rod rolling (Figure 2), grinding surface (Figure 3), polycrystalline silicon grinding square, chamfering, grinding surface (Figure 3).

3.1 Single crystal silicon rod rotary grinding wheel

Single crystal rotary grinding wheel, the normal size of 1A1 300*25 (35,40) *127*7, form of single and combination of two. FIG. 2 shows the combined roller grinding wheel with multi-particle size (D 120/140, 200/230, W40), which can achieve high machining efficiency and surface quality at the same time.

Supporting machine tools are Wuxi machine WSK003, Wuxi open source WX-7321/2, etc. (see Figure 3).

FIG. 2 Monocrystalline silicon rotary resin diamond grinding wheel

FIG. 3 Roller grinder

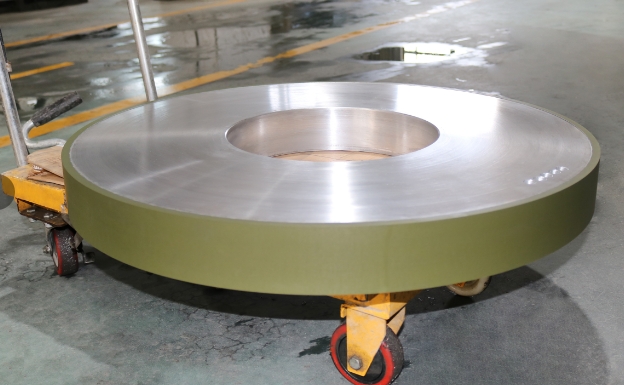

3.2 Grinding surface chamfering wheel

Monocrystal silicon grinding surface, polycrystalline silicon grinding surface chamfering, also need to use a large number of diamond wheel, processing procedures are coarse grinding, fine grinding, diamond particle size of 120/140, W40, W28, W20, etc. The main size specifications are 6A2 220*65*130*5*5, 6A2 200*60*80*5*5, 11A2 100*28(40)*31.75(20)*5*5, etc.

There are many related machine tools in China. Some surface chamfering machine can polish mono-polycrystalline arc or Angle and surface. Main supporting machine tools, grinding surface (Figure 5) : Wuxi machine WSK-009, WSK-011, WSK-015, Wuxi open source WX-7422, etc.; Chamfering (Figure 6) : Wuxi machine WSK-007, WSK-013, Wuxi open source WX-7511, WX-7522, Shijiazhuang Weifeng, etc.

4, endnotes

(1) Diamond grinding wheel, as the "tooth of industry", is increasingly showing its excellent performance in many emerging industrial materials processing fields. With the improvement of the performance of raw materials, the serialization of product specifications, the specialization of production equipment and the standardization of testing methods, diamond tools will develop towards a higher level and the quality of products will be significantly improved.

(2) with some high precision high precision diamond tools, such as photovoltaic industry ultrafine grain size of diamond grinding wheel, sapphire industry precision drill, CMP dresser and so on, there is still a gap compared with foreign products, domestic products are mainly in the performance is bad or unstable, domestic large and medium-sized enterprises will be more willing to purchase expensive foreign products, to guarantee the quality of production. This also poses a new challenge to the domestic related tool manufacturing enterprises, that is, the accuracy of products in the case of meeting the use requirements, as far as possible to improve the performance of products, and maintain the stability of product performance.

(3) Domestic products should aim at the direction of precision diamond tools. In the production process, strict product standards and technological procedures should be formulated to ensure the performance stability of products; In addition, it is necessary to equip high-precision CNC machine tools, EDM, wire cutting and other equipment for the follow-up dressing and improvement of the products.

https://www.moresuperhard.com/Products/

http://www.yubodia.com/pro_dt/productId=282.html

resin diamond grinding head with specifications of 40*35*22.5 (cone) *58 and an angle of R2

resin diamond grinding head with specifications of 40*35*22.5 (cone) *58 and an angle of R2

Resin Diamond Centerless Grinding Wheel

Resin Diamond Centerless Grinding Wheel

honored to introduce our newly launched Diamond Resin Grinding

honored to introduce our newly launched Diamond Resin Grinding