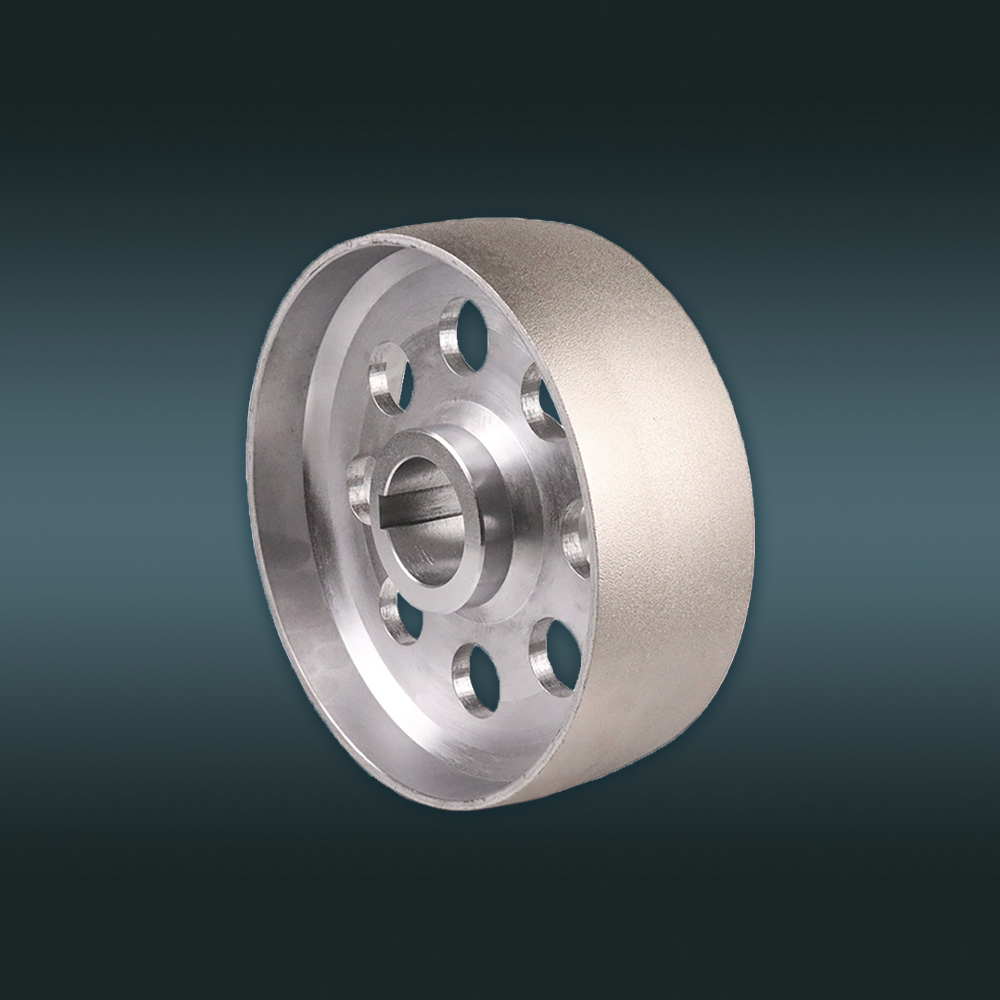

Resin Diamond Grinding Head with specifications of 40*35*22.5 (cone) *58 and an angle of R2

The conical resin diamond grinding head is a specially shaped grinding tool that combines resin binder and diamond abrasive. It has a unique conical design and is suitable for various precision machining scenarios, mainly used for grinding silicon carbide crystals.

1、 Characteristics of resin diamond grinding head

The precision of resin diamond grinding heads is high, and the conical design allows the grinding head to more accurately control the cutting angle and depth during the machining process, improving machining accuracy.

Resin diamond grinding heads have good wear resistance, and diamond abrasives have extremely high hardness and wear resistance, which can maintain sharp cutting edges for a long time and extend the service life of the grinding head.

Resin diamond grinding heads have good self-sharpening properties, and resin binders can effectively fix diamond abrasives and continuously expose new sharp edges during the machining process, maintaining good cutting performance.

Resin diamond grinding heads have a wide range of applications, and conical resin diamond grinding heads are suitable for processing various hard materials such as ceramics, optical glass, hard alloys, etc., and are widely used in the field of precision machining.

2、 The application of conical resin diamond grinding heads on silicon carbide crystals is mainly reflected in the following aspects:

High precision machining

Silicon carbide crystal is a material with high hardness and wear resistance, which requires extremely high machining accuracy. The conical resin diamond grinding head, with its unique conical design and excellent performance of diamond abrasive, can achieve high-precision cutting and grinding during the machining process. This type of grinding head can accurately control the cutting angle and depth, ensuring the smoothness and accuracy of the machined surface, and meeting the processing needs of silicon carbide crystals in high-end application fields.

Efficient removal of materials

Diamond abrasive has extremely high hardness and wear resistance, which can easily cope with the high hardness characteristics of silicon carbide crystals. During the processing, the conical resin diamond grinding head can efficiently remove materials, and reduce processing time and costs. Meanwhile, resin binders can effectively fix diamond abrasives, ensuring the stability and continuity of the grinding process.

Reduce processing damage

Silicon carbide crystals are prone to damage such as cracks and edge breakage during processing, which affects material properties and service life. The conical resin diamond grinding head, with its precise cutting and grinding capabilities, can reduce mechanical and thermal stresses during the machining process and lower the risk of machining damage. In addition, the self-sharpening of the grinding head can maintain the sharpness of the cutting edge, further reducing machining damage.

Adapt to complex shape processing

Silicon carbide crystals often need to be processed into various complex shapes in high-end applications. The conical resin diamond grinding head, with its unique conical design, can flexibly meet the processing needs of various complex shapes. Whether it is the shape of the inner hole, outer circle, or groove, precise machining can be achieved to meet the application requirements of silicon carbide crystals in different fields.

Extend service life

Due to the high hardness and wear resistance of silicon carbide crystals, traditional grinding heads are prone to severe wear during the machining process, which affects machining efficiency and accuracy. The conical resin diamond grinding head is made of diamond abrasive and resin binder, which has high wear resistance and self-sharpening, can extend the service life, and reduce the frequency and cost of replacing the grinding head.

3、 Application of Resin Diamond Grinding Heads in Other Fields

In precision machining, conical resin diamond grinding heads can be used to process various complex-shaped workpieces, such as inner holes, outer circles, grooves, etc.

In the processing of optical glass, the conical resin diamond grinding head can ensure the smoothness and accuracy of the processed surface, meeting the processing requirements of high-precision optical components.

The conical resin diamond grinding head is used to process ceramics, which have extremely high hardness and brittleness. The conical resin diamond grinding head can effectively overcome these difficulties and achieve precision machining of ceramic materials.

4、 Key points for selecting resin diamond grinding heads

The hardness, toughness, and other characteristics of different workpiece materials vary, requiring the selection of conical resin diamond grinding heads with different hardness and particle sizes.

When considering the requirements for machining accuracy, high-precision machining requires the selection of grinding heads with higher precision to ensure machining quality.

When considering processing efficiency, choosing a grinding head with higher processing efficiency can shorten processing time and reduce costs while ensuring processing quality.

5、 Precautions for using resin diamond grinding heads

Before using the conical resin diamond grinding head, it is necessary to check whether the appearance of the grinding head is intact and whether there are defects such as cracks and damage.

Correctly installing the grinding head is crucial for ensuring machining accuracy and extending the service life of the grinding head. Installation and adjustment need to be carried out according to the requirements of the machine tool manual.

During use, it is necessary to follow the operating procedures and safety regulations of the machine tool to avoid improper operation that may cause machine failure or personal injury.