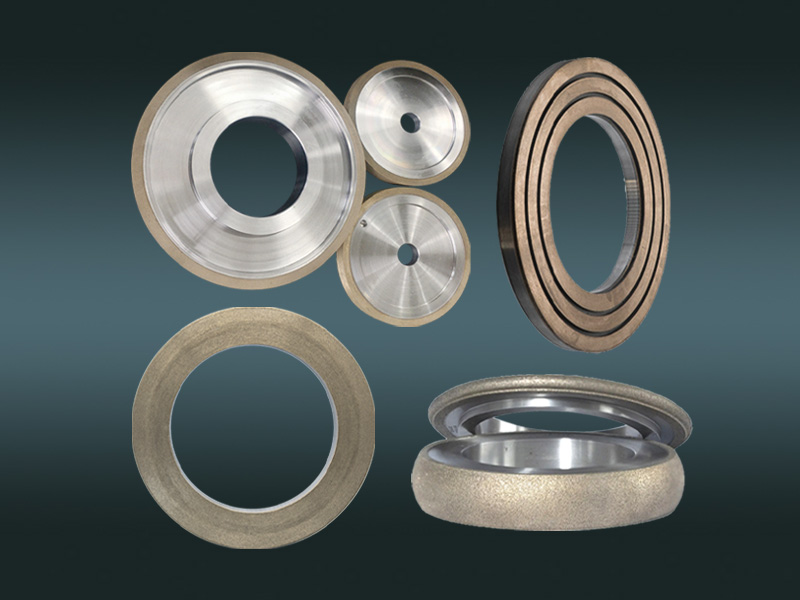

1. High grinding efficiency, sometimes it can be increased by more than 5 times.

2. Good wear resistance, 5000 to 10000 times that of general abrasives.

3. Small grinding force, only 1/4 to 1/5 of the grinding force of ordinary grinding wheels.

4. Low temperature, thermal conductivity is 17.5 times that of silicon carbide, and cutting heat can be quickly transmitted.

5. High processing accuracy and good surface quality. The surface roughness Ra value of the workpiece can generally reach 0.1 to 0.025μm, which is 1 to 2 levels higher than ordinary grinding wheel grinding.

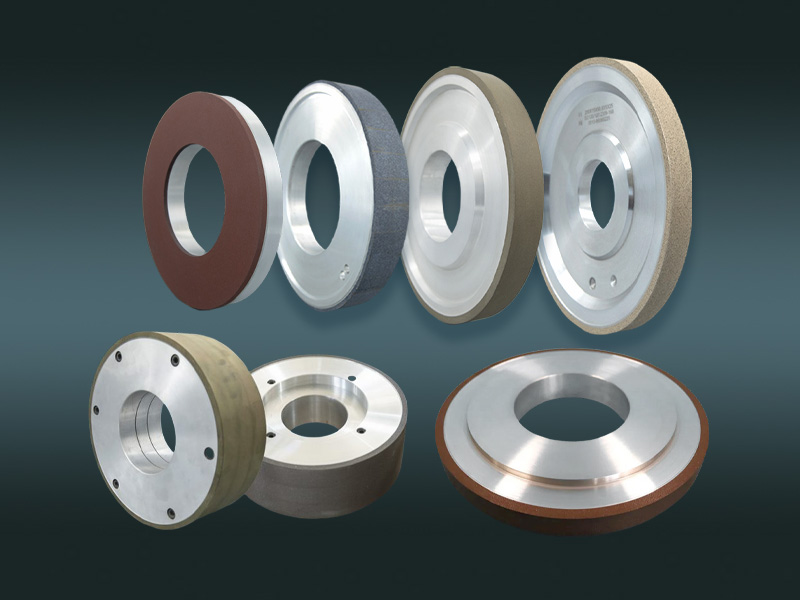

Diamond grinding wheels have high grinding efficiency, long life, are not prone to heat and clogging, and are easy to control machining accuracy and dressing. They are suitable for PCD and PCBN tool material processing. We can provide vitrified bond diamond grinding wheels and design and manufacture various non-standard grinding tools according to your requirements. They are suitable for precision grinding of super-hard tools, end faces, bevels, holes, etc.

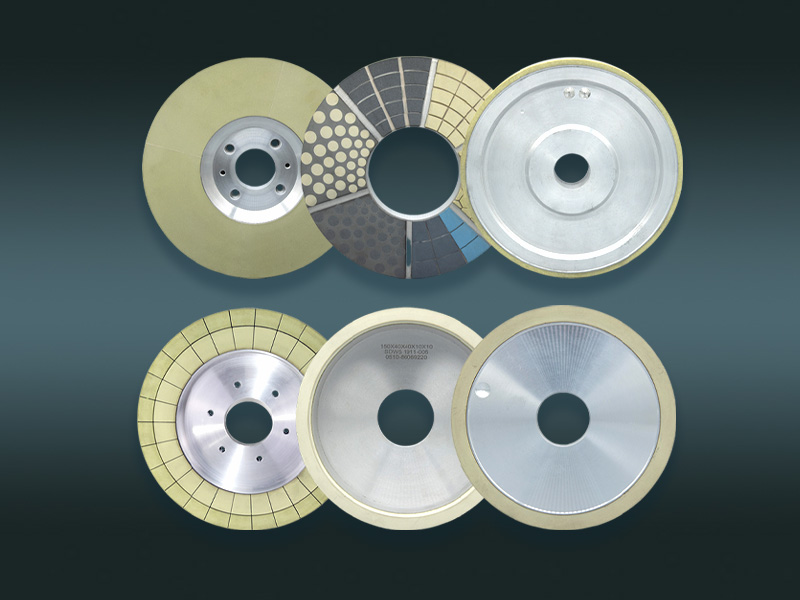

View more- Used for cutting, it can quickly and accurately cut flat glass, quartz glass or borosilicate glass.

- Used for edge grinding, it can perform high-precision edge grinding on optical glass lenses, lenses, etc., or grind the edges of glass into various shapes, such as bevel edges, round edges, duckbill edges, etc.

- Used for milling glass planes or spherical surfaces.

- Used for fine grinding and polishing of glass.

Metal diamond grinding wheels, electroplated diamond grinding wheels, and resin diamond grinding wheels are widely used in roller ring processing in steel factories. They can process tungsten steel roller rings, carbide arc forming, and high-speed wire processing.

View more