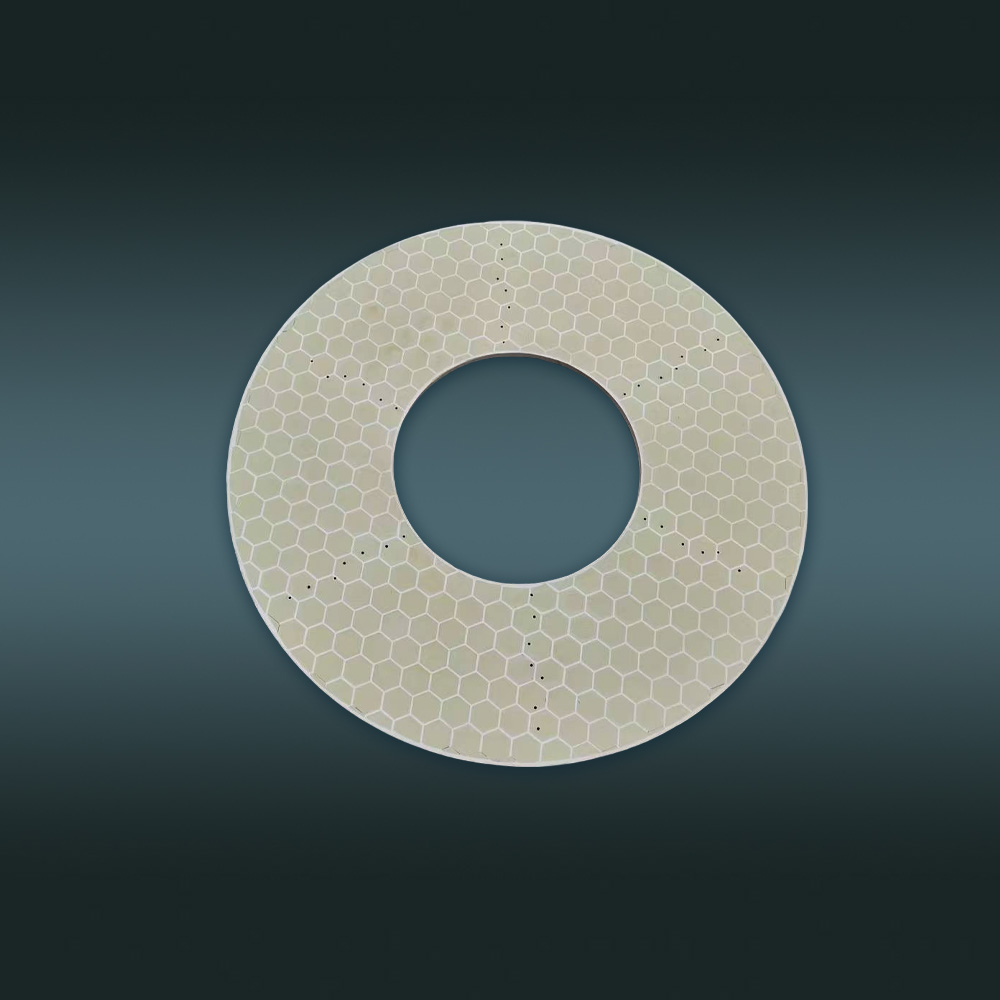

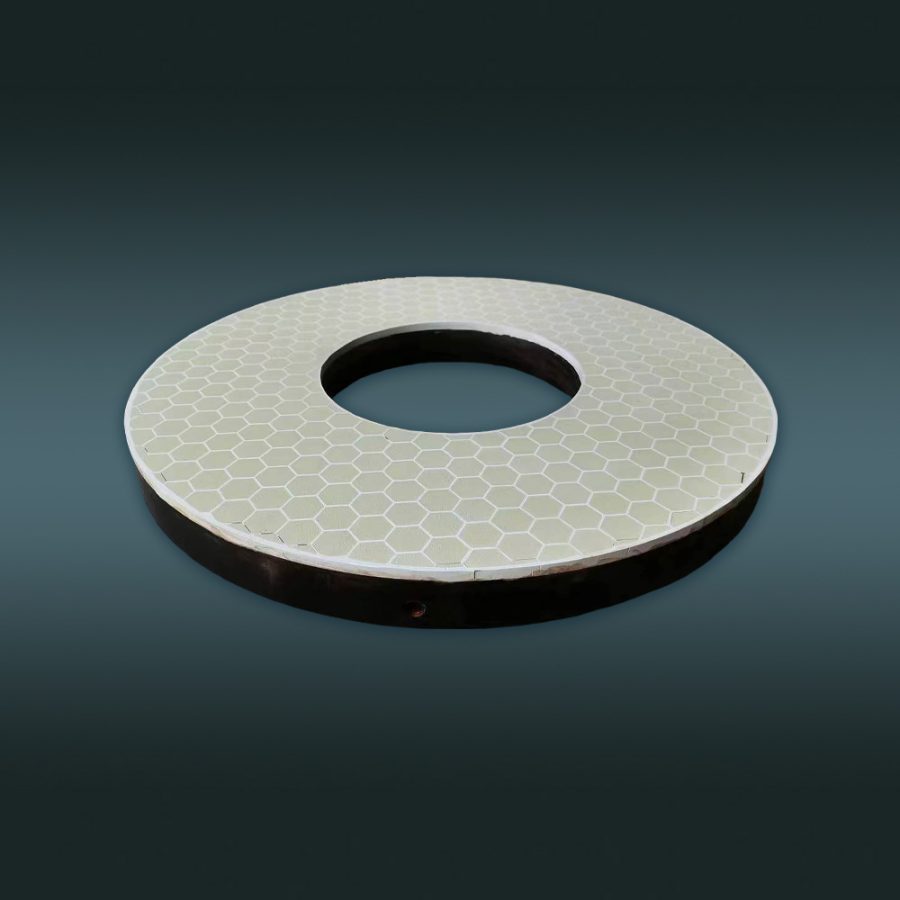

Vitrified diamond grinding disc for thinning alumina ceramic workpieces

-

Used for grinding electronic packaging substrates, optical components, and dental restoration materials made of alumina ceramic materials.

High hardness, strong wear resistance, good sharpness, and high precision.

Minimum Order Quantity: 2pcs

Net Weight: 75KG

Payment: 30% advance

- Whatspp:+86 13357928197

- E-mail:wang@jyxhzs.com

Detail

Description

Vitrified diamond grinding discs have high hardness and good wear resistance, making them an effective tool for grinding alumina ceramic workpieces. During the grinding process, it is important to choose appropriate grinding parameters such as grinding speed, grinding pressure, and grinding time.

Specifications

| Place of Origin | China |

| Brand Name | Jiangsu Xingzuan Superhard Material Technology Co., Ltd |

| Certification | CNIPA |

| Abrasive | Diamond |

| Bond | Vitrified bond |

| Abrasive Grit Size | 80/100 |

| Model Number | 2P2 |

| Outside Diameter | 610mm |

| Total Thickness | 30mm |

| Net Weight | 75KG |

| Minimum Order Quantity | 2pcs |

| Delivery Time | 30 days from advance payment |

| Supply Ability | Support customization |

| Payment | 30% advance |

Applications

- Used for grinding electronic packaging substrates made of alumina ceramic material to ensure their surface flatness and dimensional accuracy.

- Used for manufacturing ceramic mechanical components, such as ceramic bearings, ceramic valves, etc.

- Used for high-precision grinding and polishing of optical components made of alumina ceramic material.

- Used for fine grinding of ceramic cores and sleeves made of alumina ceramic materials.

- Used for grinding as dental restoration materials and surgical treatment tools.

Competitive Advantage

- High hardness and strong wear resistance, the grinding disc can maintain good grinding performance.

- It can easily cut into the surface of alumina ceramics, achieve efficient grinding, reduce damage to the workpiece, and minimize defects such as cracks and chipping.

- High processing accuracy and grinding efficiency.