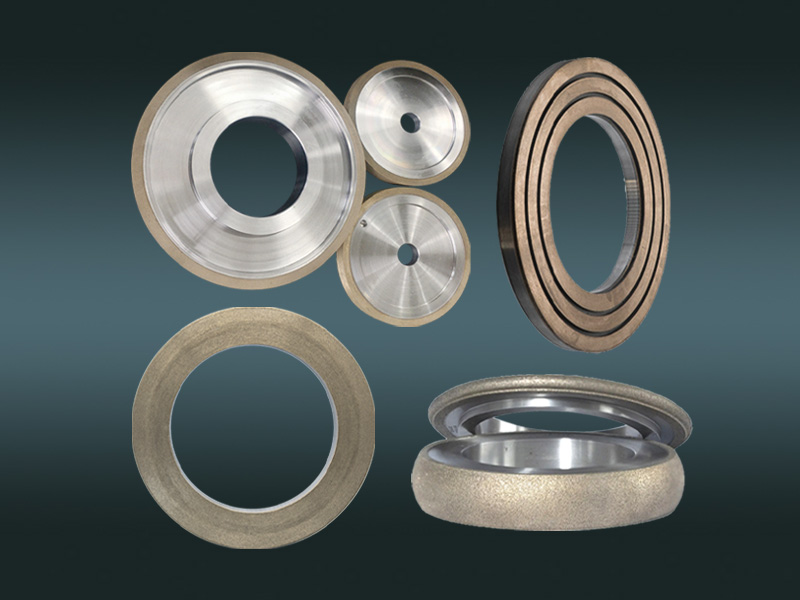

Diamond Wheel For Steel Factory

-

Metal diamond grinding wheels, electroplated diamond grinding wheels, and resin diamond grinding wheels are widely used in roller ring processing in steel factories. They can process tungsten steel roller rings, carbide arc forming, and high-speed wire processing.

- Whatspp:+86 13357928197

- E-mail:wang@jyxhzs.com

Detail

Do steel factories need diamond grinding wheels or CBN grinding wheels?

Diamond and CBN grinding wheels are used, and the specific type of grinding wheel to be used depends on many factors.

Processing materials

Generally, diamond grinding wheels are not used to process steel materials. Diamonds will react chemically with iron at high temperatures, resulting in the carbonization of abrasive grains and reduced strength.

CBN grinding wheels are suitable for processing a variety of steel materials in steel factories, such as alloy steel, high-speed steel, various hardened steels, chilled cast iron, etc., and there will be no sticking during grinding.

Processing accuracy requirements

Diamond grinding wheels have good cutting performance and low grinding force. In some occasions with extremely high processing accuracy requirements, such as steel processing in aerospace, mold manufacturing, and other fields, diamond grinding wheels can meet high precision and low surface roughness processing requirements.

CBN grinding wheels can enable the workpiece to achieve higher dimensional accuracy and good surface quality, and the processed surface is not prone to cracks and burns. They are suitable for grinding precision rollers, bearings, and other parts in steel factory production.

What kind of bond diamond grinding wheel can be selected?

Metal bond

For rough grinding of high-hardness alloy steel, high-speed steel, carbide rollers, and other workpieces, metal bonds such as our company's bronze bond diamond grinding wheel are a good choice. When the roller is first processed or repaired, a large amount of material needs to be removed. The metal bond grinding wheel has high strength and good wear resistance and can withstand large grinding forces. It can efficiently remove metal excess, and the service life of the grinding wheel is relatively long. It can maintain good performance in long-term and high-intensity grinding work, reduce the number of frequent replacements of grinding wheels, and improve production efficiency.

Resin bond

When it comes to fine grinding and polishing of some steel products with high surface quality requirements, such as precision mold steel, resin bond diamond grinding wheels are more suitable. It has good self-sharpening and generates less heat during grinding. During the fine grinding process, the elasticity of the resin bond can better fit the surface of the workpiece, help to obtain a better surface finish, and prevent the steel surface from being damaged due to overheating or uneven grinding force.

Why choose our products?

1. We use better diamond abrasives and imported binders to ensure good raw materials and good product quality.

2. We have professional engineers to supervise and control production and strict quality inspection departments to ensure product quality again.

3. We can customize according to customer needs, using special formulas to ensure good grinding effects, high grinding efficiency, and long service life.

4. We have a good sales team, after-sales team, and technical team to provide free services to customers at any time to ensure that there are no problems with customer use.