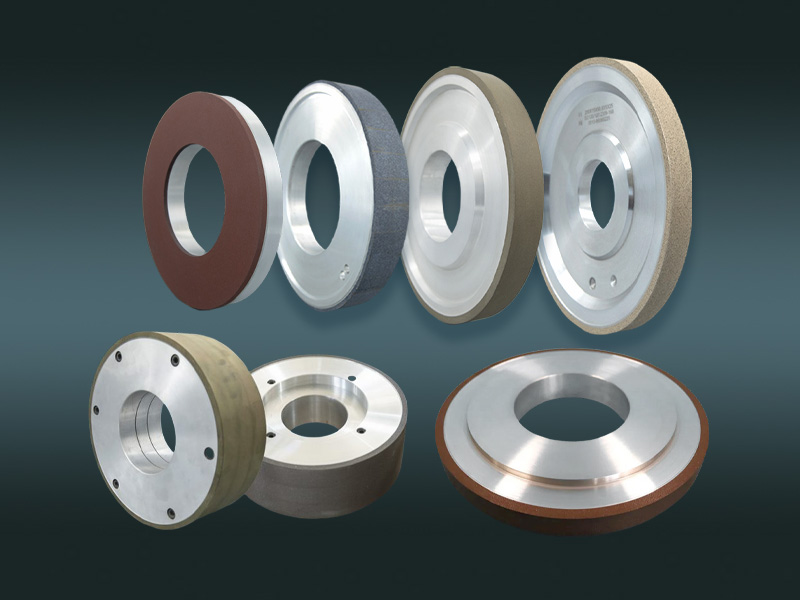

Diamond Wheel For Carbide Alloy

-

1. High grinding efficiency, sometimes it can be increased by more than 5 times.

2. Good wear resistance, 5000 to 10000 times that of general abrasives.

3. Small grinding force, only 1/4 to 1/5 of the grinding force of ordinary grinding wheels.

4. Low temperature, thermal conductivity is 17.5 times that of silicon carbide, and cutting heat can be quickly transmitted.

5. High processing accuracy and good surface quality. The surface roughness Ra value of the workpiece can generally reach 0.1 to 0.025μm, which is 1 to 2 levels higher than ordinary grinding wheel grinding.

- Whatspp:+86 13357928197

- E-mail:wang@jyxhzs.com

Detail

Do we need diamond grinding wheels or CBN grinding wheels to grind carbide alloy?

Diamond grinding wheels are usually selected. Carbide alloy is an alloy material made of hard compounds of refractory metals and bonding metals through powder metallurgy. The main component is tungsten carbide, also known as tungsten steel. It does not react chemically with diamonds. At the same time, it has high strength, hardness, and wear resistance. Its toughness is poor and brittle.

What kind of bond can be selected for diamond grinding wheels?

Metal bond

For example, our company's bronze bond diamond grinding wheel has high strength and wear resistance, good formability, strong heat dissipation, long service life, can withstand large grinding forces, and performs well in rough grinding of carbide alloy. For example, when processing the blank of carbide alloy tools, the excess can be removed efficiently. However, if the surface porosity of the grinding wheel is insufficient, it is easy to cause the surface of the grinding wheel to be blocked, or the grinding wheel is easy to wear, and a large amount of processing heat is generated, resulting in burns on the surface of the workpiece.

Resin bond

The resin bond diamond grinding wheel is sharp, efficient, self-sharpening, not easy to block, generates less heat during grinding, and has a polishing effect, which is particularly commonly used. It is suitable for fine grinding and forming grinding of carbide alloy. For example, when grinding the complex shape surface of carbide alloy molds, the elasticity of the resin bond can better fit the workpiece, reduce surface damage, and obtain a better surface finish.

Vitrified bond

The vitrified bond diamond grinding wheel has excellent wear resistance and chemical stability, high grinding efficiency, and is very advantageous in processing high-precision and high-hardness carbide alloy workpieces. This kind of grinding wheel can be used for precision grinding of some carbide parts used in the aerospace field.

Why choose our products?

1. We use better diamond abrasives and imported binders to ensure good raw materials and good product quality.

2. We have professional engineers to supervise and control production and strict quality inspection departments to ensure product quality again.

3. We can customize according to customer needs, using special special formulas to ensure good grinding effect, high grinding efficiency and long service life.

4. We have a good sales team, after-sales team, and technical team to provide free services to customers at any time to ensure that there are no problems with customer use.