What is the hardness of grinding wheel?

The hardness of grinding wheel refers to the adhesive strength of the bond to the abrasive(how easy it is for the abrasive to detach from the grinding wheel). The hardness of the grinding wheel is determined by the bonding strength of the binder, not by the hardness of the abrasive. Under the same conditions and certain external force, if the abrasive particles are very easy to fall off from the grinding wheel, the hardness of the grinding wheel will be relatively low (or soft). On the contrary, the hardness of the grinding wheel is relatively high (or hard).

What is self-sharpening of grinding wheel?

After the abrasive particles on the grinding wheel are passivated, the grinding force acting on the abrasive particles increases, which makes the surface abrasive particles of the grinding wheel fall off automatically, and the sharp cutting edge of the new abrasive particles in the inner layer is put into cutting, and the grinding wheel recovers its original cutting performance. This ability of grinding wheel is called "self-sharpening".

Whether the grinding wheel hardness is reasonable or not has great influence on the grinding quality and productivity. Generally speaking, the harder the component material, the softer the grinding wheel should be. This is because the hardness of the parts is high and the abrasive wear is fast. Choosing a softer grinding wheel is conducive to the "self-sharpening" of the grinding wheel. However, if the hardness is too low, the grinding wheel will wear quickly and it is difficult to ensure the correct sand profile. If the hardness of the grinding wheel is too high, it is difficult to realize the self-sharpening of the grinding wheel, which is not only low productivity, but also easy to produce high temperature burns on the surface of parts.

If the grinding wheel is soft, it is easy to dressing, but the retention of shape and contour is usually not ideal. In order to improve the surface roughness of the workpiece, the hardness of the grinding wheel is too high will occur heat and shake, resulting in the problem of poor surface roughness.

Importance of cutting force

If the forming wheel to maintain the force, the best way is increasing the hardness of the wheel. However, it is easy to occur the problem of cutting force, if the grinding wheel cutting force is good, grinding resistance is small, in addition to the speed of feeding can be accelerated, the heat will be less, the grinding wheel cooling and heat change degree is small, the grinding wheel consumption will be less. If only hardness is required, the grinding temperature may rise even higher and the grinding wheel consumption may even speed up.

Enhancement of bond

The choice of abrasive particle size is mainly related to the surface roughness and productivity.

Bond is the key to the self-sharpening of grinding wheel and the main determinant of the hardness of grinding wheel.

In terms of forming grinding, the requirements of bond, in addition to balance cutting force and shape holding force, if the heat dissipation and grinding ratio can be further improved, the grinding efficiency will be greatly improved.

In addition to the significant improvement of the grinding ratio, the reduced binder also means that the space of the pores is made available, the space for heat dissipation is increased and the chance of blockage is reduced.

|

Bond |

Characteristics |

|

Ceramic bond |

Good chemical stability, heat resistance, corrosion resistance, cheap, accounting for 90%, but brittle, should not be made into thin sections, should not be high-speed, linear speed is generally 35m/s |

|

Resin bond |

High strength, good elasticity, impact resistance, suitable for high-speed grinding or cutting grooves and other work, but poor corrosion resistance and heat resistance (300℃), good self-sharpening. |

|

Metal bond |

Bronze, nickel, etc., high strength and toughness, good formability, but poor self-sharpening, suitable for diamond, cubic borax nitride wheel. |

Coarse grinding

During coarse grinding, the grinding allowance is large, the required surface roughness value is large, should choose a coarser abrasive. Because of coarse abrasive particles, large pores and large grinding depth, the grinding wheel is not easy to block and heat.

Fine grinding

In fine grinding, the allowance is small and the required roughness value is low, so fine grinding particles can be . Generally speaking, the finer the abrasive particles, the better the grinding surface roughness. Granularity is not the only factor that plays a decisive role. I have seen mirrors made with 80K grinding wheels. See Table 3 for the application of grinding wheels with different grain sizes.

Not "hard" is suitable

In the selection of forming grinding wheel, the most important thing is to avoid the blind spot of grinding wheel hardness. In fact, more attention should be paid to the basic performance of grinding wheel such as cutting force, organization uniformity and heat dissipation, so as to select the most suitable product.

The hardness of grinding wheel:

|

Hardness |

|

|

Workpiece |

Grinding wheel |

|

HRC<45 |

M |

|

HRC<45-55 |

L |

|

HRC<50-60 |

K |

|

HRC<58-62 |

J |

|

HRC<60-65 |

H |

resin diamond grinding head with specifications of 40*35*22.5 (cone) *58 and an angle of R2

resin diamond grinding head with specifications of 40*35*22.5 (cone) *58 and an angle of R2

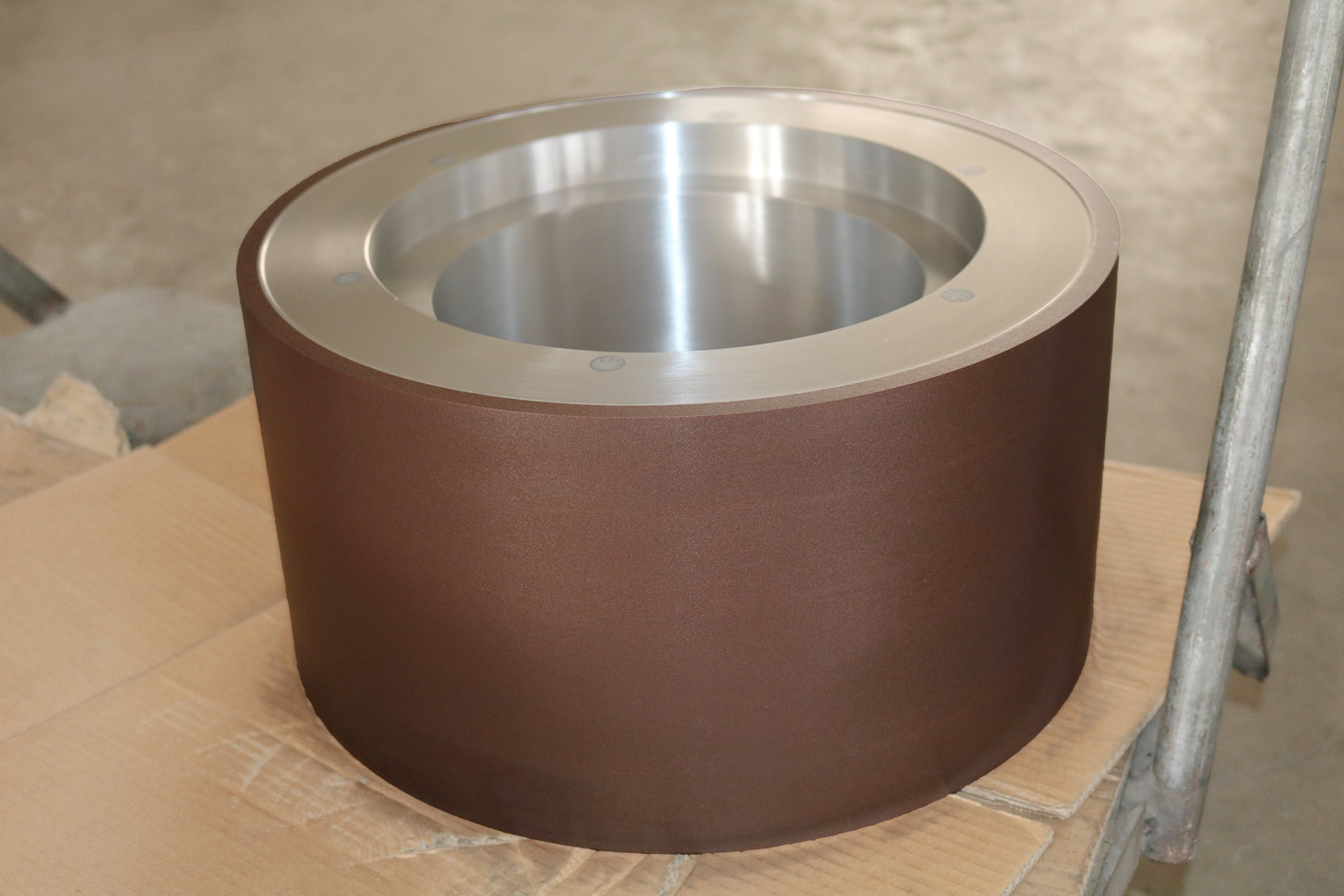

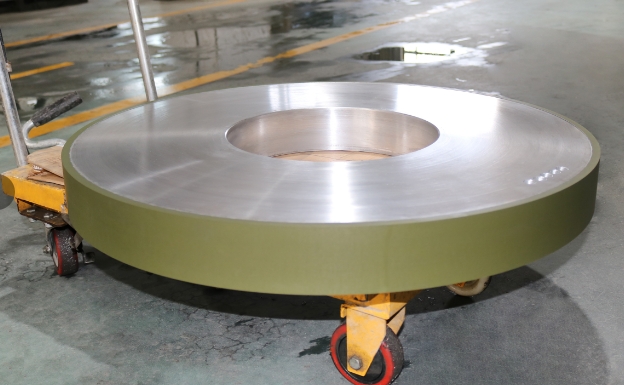

Resin Diamond Centerless Grinding Wheel

Resin Diamond Centerless Grinding Wheel

honored to introduce our newly launched Diamond Resin Grinding

honored to introduce our newly launched Diamond Resin Grinding