Application of Vitrified Bond Diamond Grinding Wheel on Hard Alloy Materials

With the continuous growth of new materials, mechanical processing is developing towards high quality, high precision, high efficiency, and automation. The application range of vitrified diamond grinding wheels is also becoming wider and their usage is constantly increasing. Vitrified bond diamond grinding wheels are mainly used in the mechanical processing of high hardness and brittleness materials such as hard alloys, semiconductor silicon wafers, diamond composite sheets, diamond cutting tools, new engineering structural vitrified, gemstones, crystals, magnetic materials, etc., and have achieved good results.

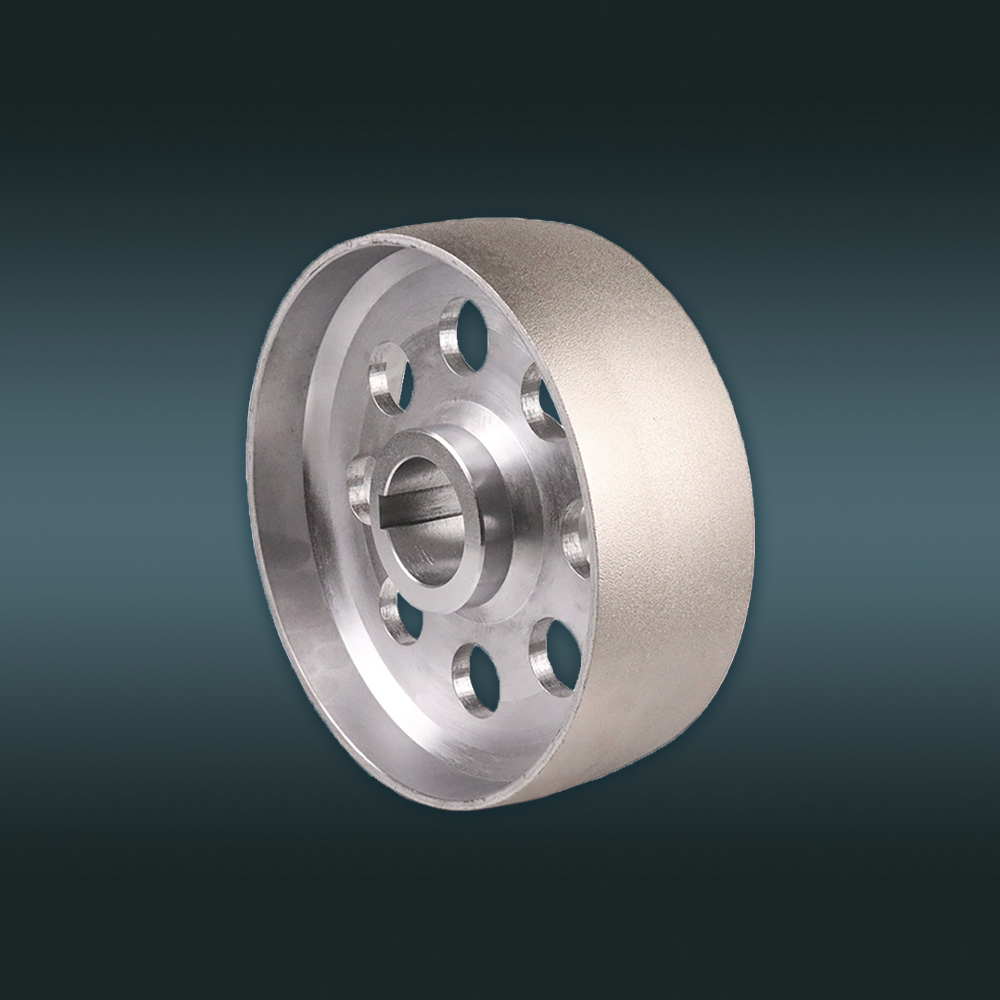

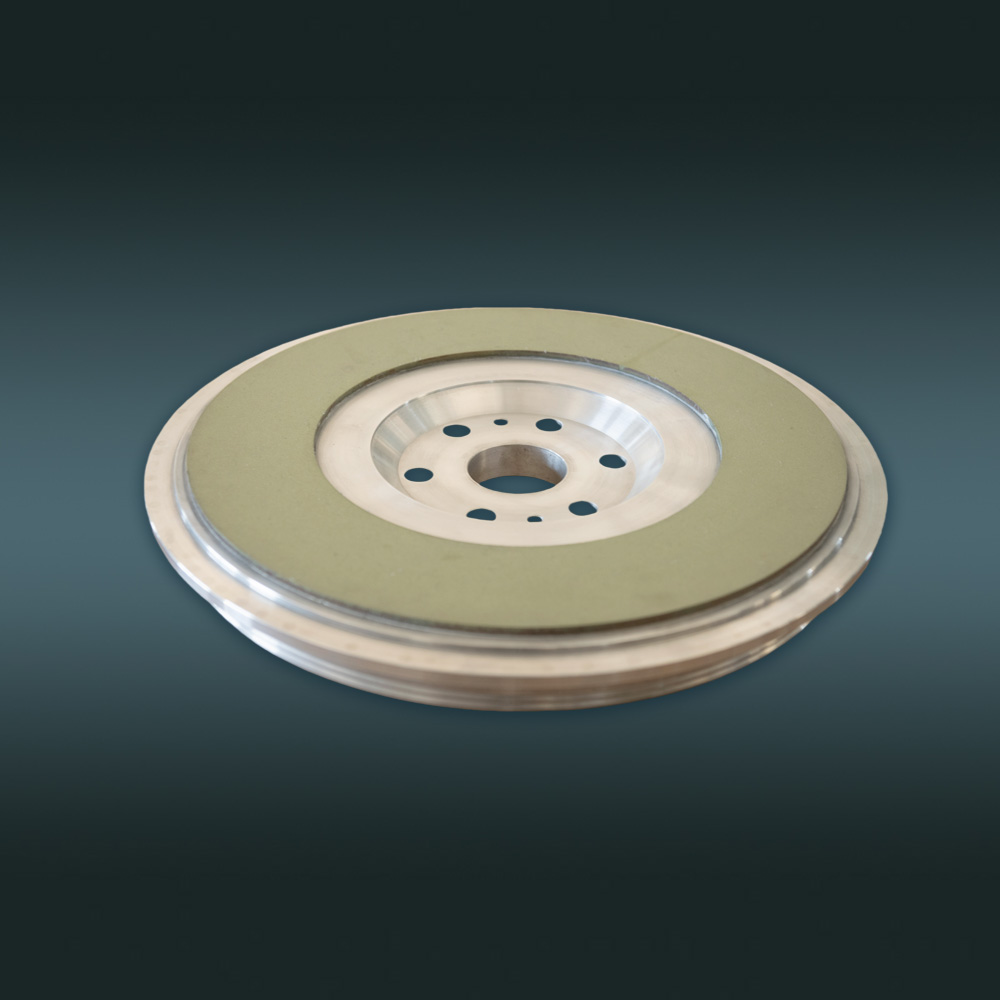

Vitrified bond diamond grinding wheels have the characteristics of high strength, good heat resistance, sharp cutting, high grinding efficiency, low heat generation, and blockage during the grinding process, small thermal expansion, good shape retention, and easy control of machining accuracy. Compared with resin diamond grinding wheels, it solves the problems of low service life, low grinding efficiency, poor shape retention, and easy deformation of the grinding tool itself during the grinding process. Hard alloy has a series of excellent properties such as high hardness, wear resistance, high strength, and corrosion resistance, especially its high hardness and wear resistance. With the development of technology, cemented carbide has been widely used as tool material, replacing traditional high-speed steel, such as cutting tools, milling cutters, planers, etc. Some scholars have proposed the concept of "cutting instead of grinding", which puts higher demands on the surface processing quality of cemented carbide.

At present, for the grinding of hard alloy cutting tools, most manufacturers still choose resin diamond grinding wheels. Although they can also achieve the grinding results we want, the grinding efficiency is very low. For resin diamond, a particle size of 100-120 mesh is generally used for rough machining, while for vitrified diamond grinding wheels, we generally use a particle size of 120-150 mesh for rough machining. Even with higher metal removal rates, better surface smoothness can still be achieved.

Vitrified bonding agents bond diamonds more firmly than resin bonding agents, and there are larger pores between the abrasive particles and the bonding agent, each pore equivalent to the chip space on the cutting edge of a single-point cutting tool. For the same grinding allowance, the grinding efficiency of the vitrified diamond grinding wheel is about twice that of the resin diamond grinding wheel, and its service life is 2-3 times that of the resin diamond grinding wheel.

The widespread application, increasing variety, and continuous improvement of the quality of hard alloy cutting tools require better surface processing quality of hard alloys. Vitrified bond diamond grinding wheels, due to their good shape retention, fundamentally solve this problem, greatly improving grinding efficiency, production costs, and grinding accuracy. The development and promotion of this technology have brought about a qualitative change in the overall cost and efficiency of tool manufacturers.