Why does the workpiece still have texture after fine grinding and polishing?

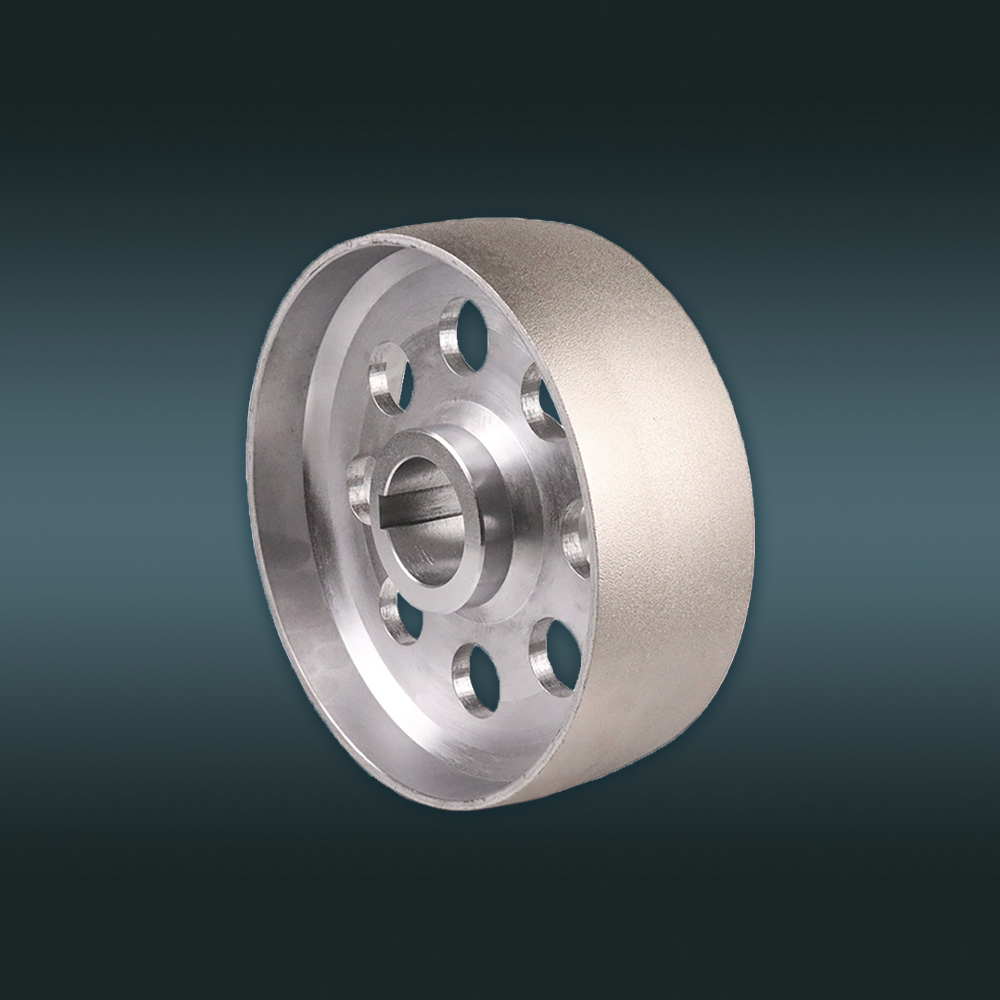

1) Grinding wheel and its use problems: If the surface of the grinding wheel has defects such as gaps and pores, it will lose its smoothness and form ripples or textures. The mismatch between the grinding wheel formula, particle size, structure, and other parameters and the workpiece being processed will also cause the grinding surface to be uneven and have textures.

2) The grinding wheel is too coarse during rough grinding, and the grinding marks cannot be removed during fine grinding and polishing.

3) Insufficient machine tool accuracy or poor stability will cause the grinding wheel to vibrate or jump during the grinding process, leaving textures on the workpiece surface.

What can be done?

- Replace the grinding wheel, select the appropriate grinding wheel for fine grinding and polishing, ensure that there is no problem with the grinding wheel's production, and select the grinding wheel with parameters that match the workpiece.

- Use a grinding wheel with finer grain size. At the same time, ensure that the grinding wheel is well-balanced after installation.

- Optimize the process parameters and adjust the feed speed to make it slower and more uniform. For example, according to the material and size of the workpiece, reduce the feed speed to a suitable value; reduce the grinding depth, and use multiple small depth grinding to gradually meet the processing requirements.