Category

Related

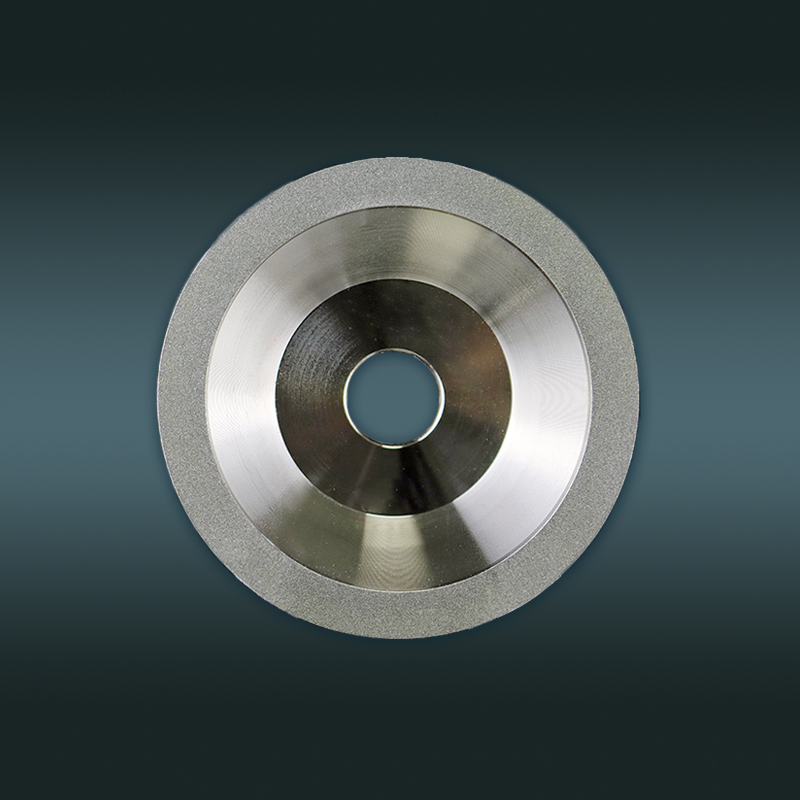

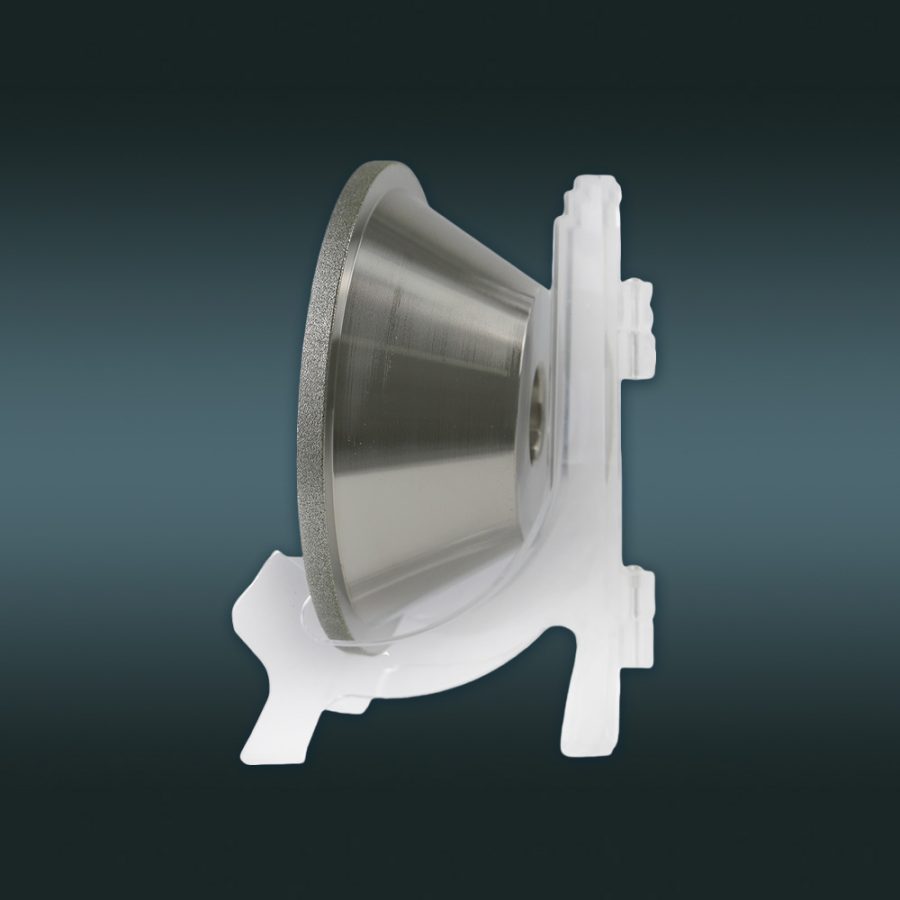

Bowl-shaped electroplated diamond grinding wheel with a diameter of 100mm

-

It can be used in machining, semiconductor materials, glass plates, and daily necessities.

Sharp, high processing efficiency and can be applied to complex surface processing.

Minimum Order Quantity: 50pcs

Net Weight: 450g

Payment:30% advance

- Whatspp:+86 13357928197

- E-mail:wang@jyxhzs.com

Detail

Description

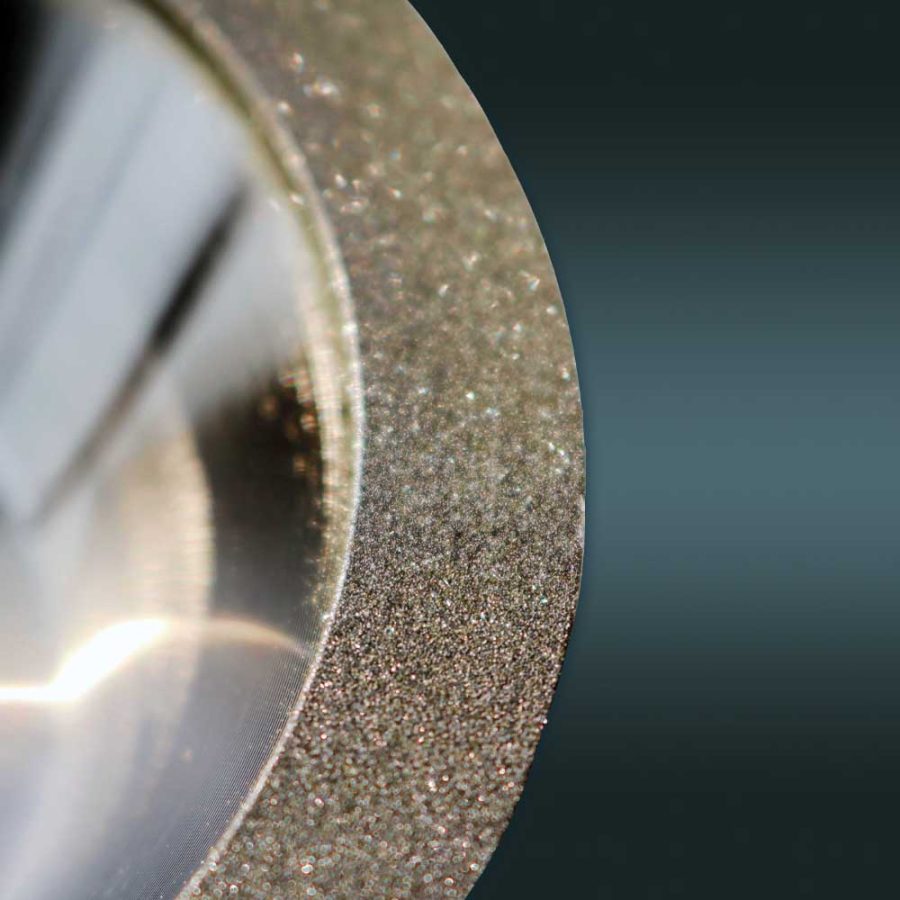

The bowl-shaped electroplated diamond grinding wheel with the thickness of the metal bond is 20% of the height of the diamond abrasive grain. Then the metal bond continues to bond the diamond abrasive grain with the metal bond to a thickness of about 2/3 of the height of the abrasive grain, including diamond dressing wheels, and electroplated diamond wheels for grinding or cutting.

The bowl-shaped electroplated diamond grinding wheel with the thickness of the metal bond is 20% of the height of the diamond abrasive grain. Then the metal bond continues to bond the diamond abrasive grain with the metal bond to a thickness of about 2/3 of the height of the abrasive grain, including diamond dressing wheels, and electroplated diamond wheels for grinding or cutting.

Specifications

| Place of Origin | China |

| Brand Name | Jiangsu Xingzuan Superhard Material Technology Co., Ltd |

| Certification | CNIPA |

| Abrasive | Diamond |

| Bond | Electroplating bond |

| Abrasive Grit Size | 80# 100# 150# 200# 320# 400# and 600# |

| Specification | 100*35*20*10*5 |

| Net Weight | 560g |

| Model Number | 12A2 |

| Concentration | 200% |

| Net Weight | 450g |

| Minimum Order Quantity | 50pcs |

| Delivery Time | 30 days from advance payment |

| Supply Ability | Support customization |

| Payment | 30% advance |

Applications

High abrasive concentration, sharpness, and high processing efficiency. It is particularly suitable for grinding hard and brittle non-metallic materials such as glass, gemstones, crystals, and magnetic materials.

Competitive Advantage

- The electroplating process is simple, the investment is low, and the manufacturing is convenient.

- Sharp, high processing efficiency can be applied to complex surface processing.

- No trimming is required, and it is easy to use.

- Very high working speeds can be achieved.