Category

Related

-

Electroplated diamond grinding wheel for glass edge grinding

-

Superhard Material Products Saw Blade Electroplated Diamond Dresser Wheel for Auto Parts

-

Bowl-shaped electroplated diamond grinding wheel with a diameter of 100mm

-

Electroplated Diamond Hand Polishing Pads for Glass Granite Marble Concrete Sanding Blocks

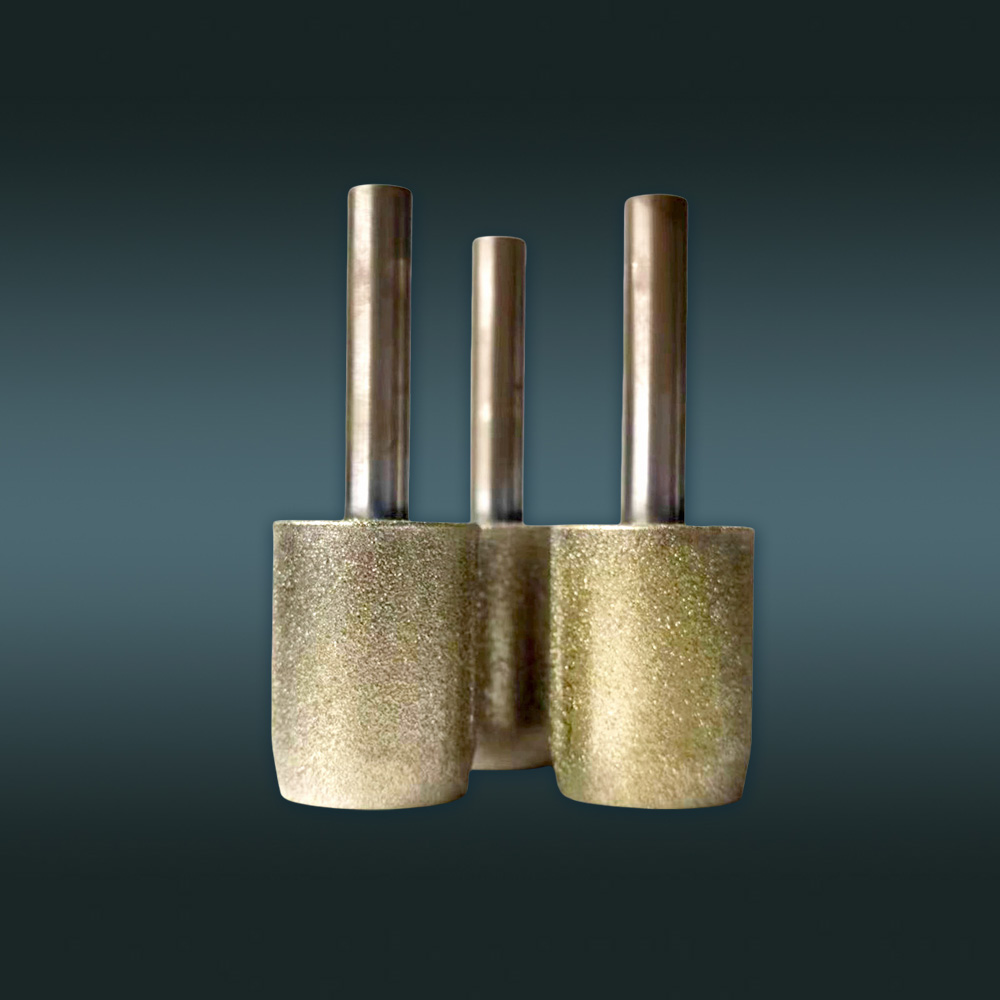

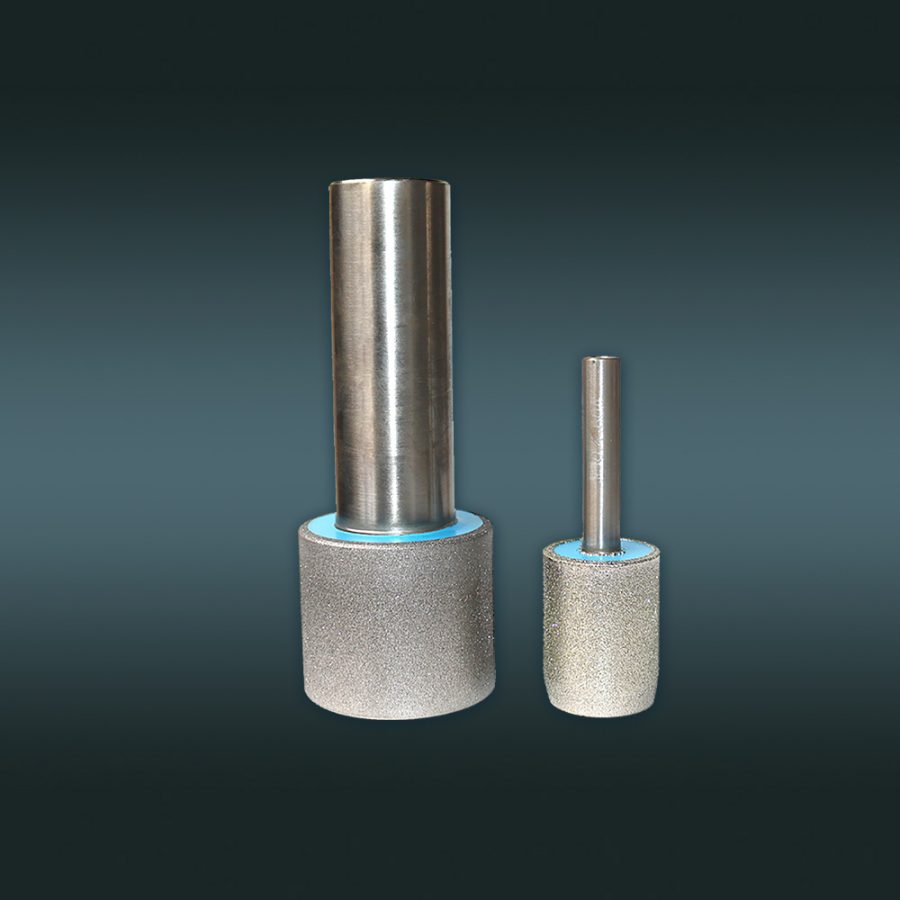

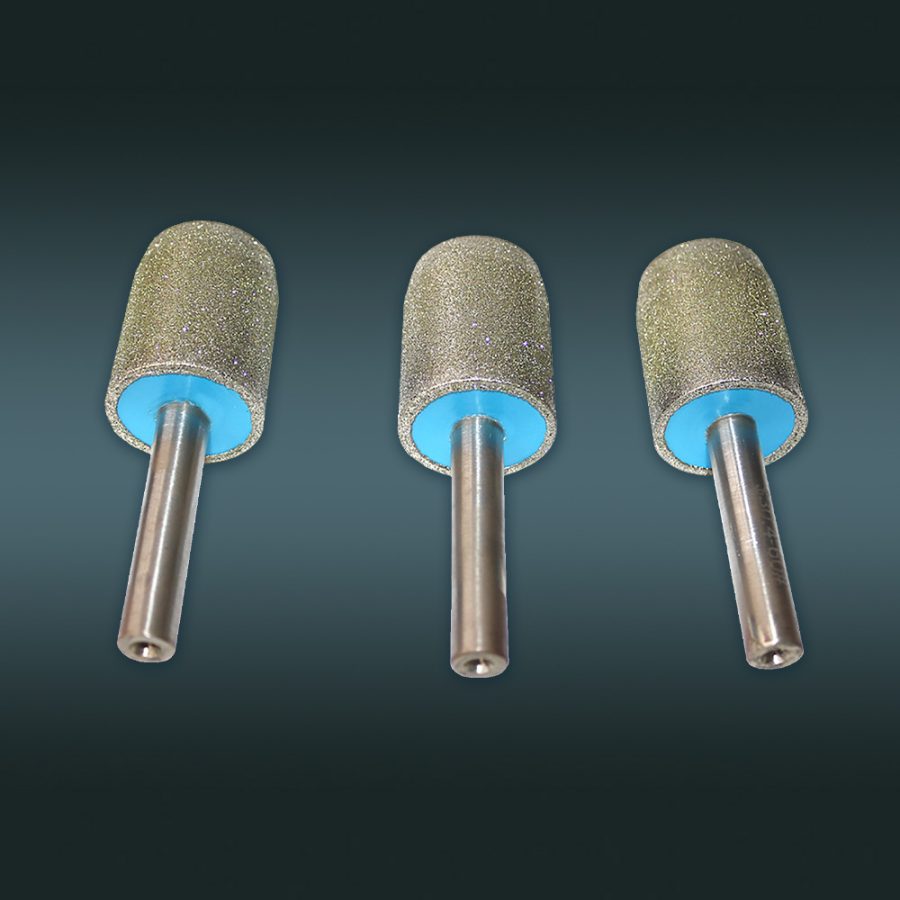

Electroplated diamond & CBN grinding rod for inner edge grinding

-

Electroplated diamond and CBN internal grinding rods are widely used in the industrial field.

High hardness, good wear resistance, and high-temperature resistance.

Minimum Order Quantity: 30pcs

Net Weight: 21g

Payment: 30% advance

- Whatspp:+86 13357928197

- E-mail:wang@jyxhzs.com

Detail

Description

The electroplated diamond internal grinding rod is a widely used superhard grinding tool in the industrial field, playing an important role in material processing and precision manufacturing. It has excellent hardness, density, wear resistance, and high-temperature resistance.

Specifications

| Place of Origin | China |

| Brand Name | Jiangsu Xingzuan Superhard Material Technology Co., Ltd |

| Certification | CNIPA |

| Purpose of grinding wheel | Inner edge grinding |

| Abrasive | Diamond/CBN |

| Bond | Electroplating bond |

| Abrasive Grit Size | 70/80 |

| Length | 28mm |

| Model Number | DW |

| Net Weight | 21g |

| Minimum Order Quantity | 30pcs |

| Delivery Time | 30 days from advance payment |

| Supply Ability | Support customization |

| Payment | 30% advance |

| Guarantee period | 1 year |

Applications

- Used for processing high-precision workpieces such as crankshafts, bearings, hydraulic valves, etc.

- Processing and grinding molds made of hard alloys or quenched hard steel, as well as various shapes of workpiece surfaces and inner holes.

- Used for processing hard and brittle materials such as semiconductors and graphite, as well as carbon materials commonly used in electric heating equipment.

- Used for processing difficult-to-machine materials such as alloys, hard steels, and quenched steels.

Competitive Advantage

- It has excellent hardness, density, wear resistance, and high-temperature resistance, which can significantly improve the performance of grinding rods.

- It can directly form and grind workpieces, with advantages such as high precision, high efficiency, and durability.