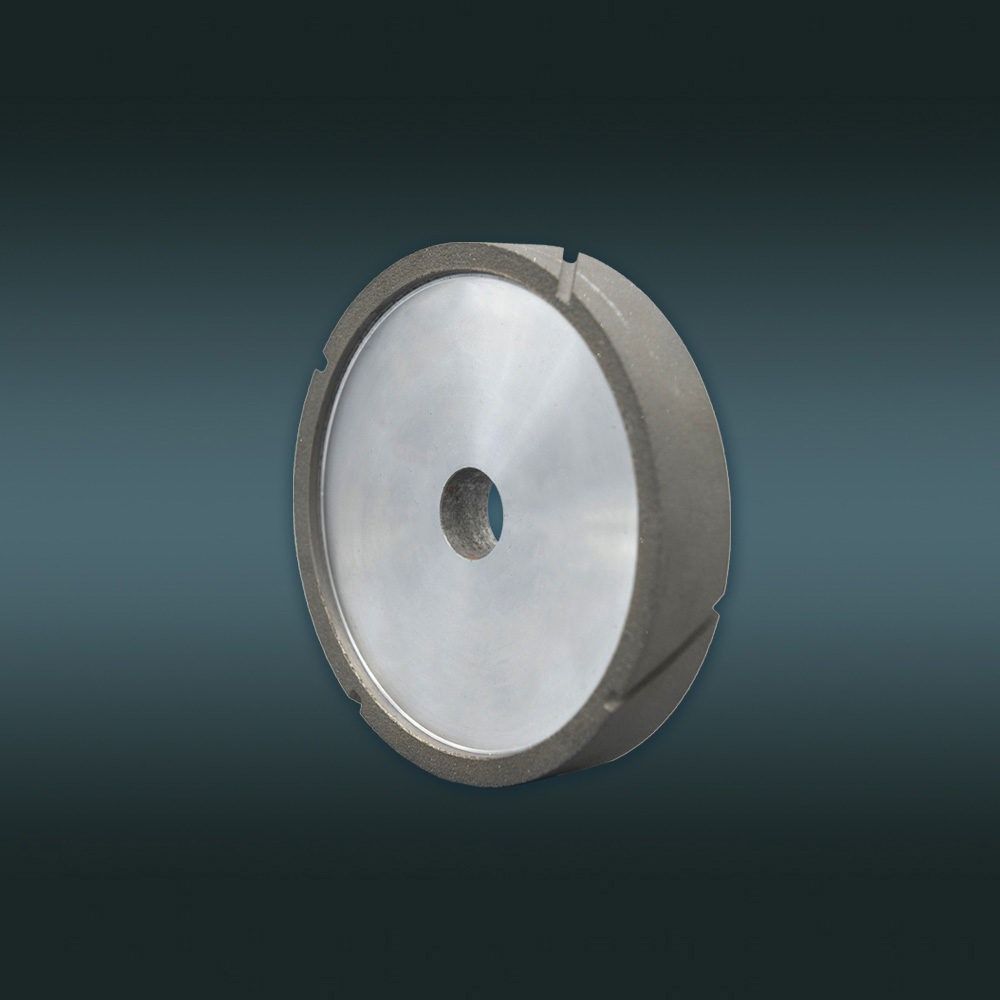

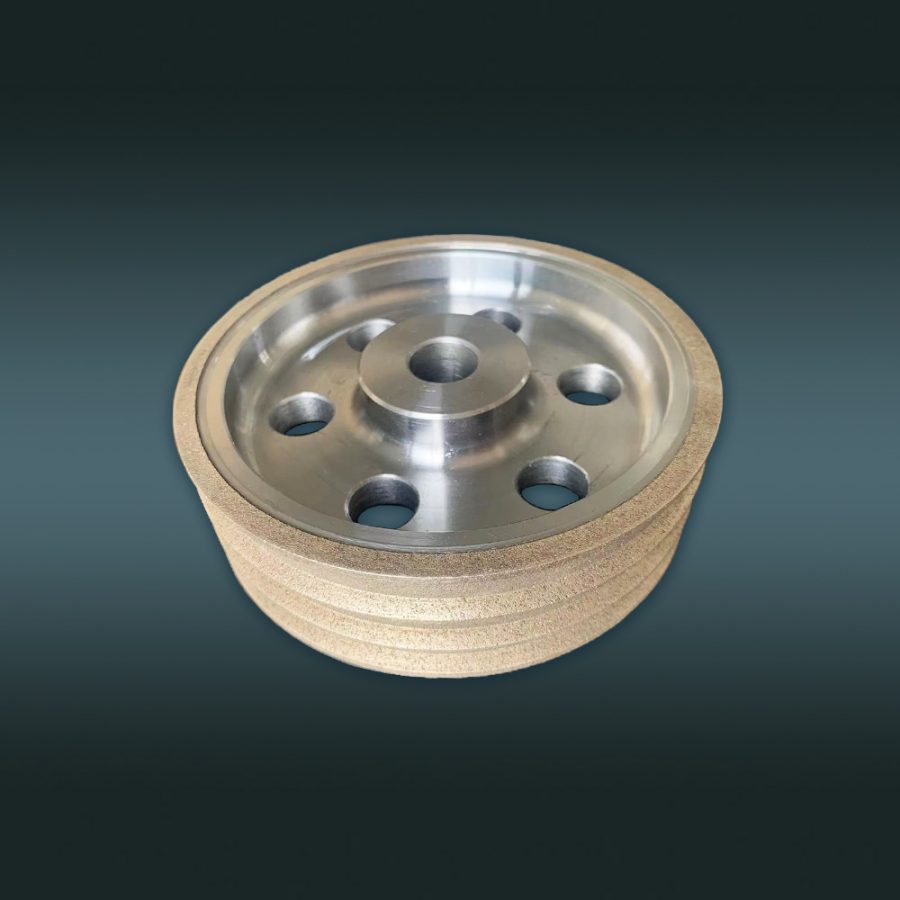

1A1 Metal Diamond Grinding Wheel with Chip Groove

-

Used for processing hard alloys, optical lenses, ceramics, glass, etc.

Good chip removal performance, reduces wheel blockage, and improves processing efficiency.

Minimum Order Quantity: 10pcs

Net Weight: 560g

Payment: 30% advance

- Whatspp:+86 13357928197

- E-mail:wang@jyxhzs.com

Detail

Description

The metal chip removal groove can timely discharge the grinding debris generated by the workpiece, avoid the accumulation of grinding debris, reduce the friction between the grinding wheel and the workpiece, and ensure the grinding effect of the grinding wheel and the machining accuracy of the workpiece.

Specifications

| Place of Origin | China |

| Brand Name | Jiangsu Xingzuan Superhard Material Technology Co., Ltd |

| Certification | CNIPA |

| Abrasive | Diamond |

| Bond | Bronze bond |

| Abrasive Grit Size | Support customization |

| Model Number | 1A1 |

| Outside Diameter | 180mm |

| Net Weight | 560g |

| Minimum Order Quantity | 10pcs |

| Delivery Time | 30 days from advance payment |

| Supply Ability | Support customization |

| Payment | 30% advance |

Applications

- Used for grinding high-precision tool edges such as milling cutters and drill bits for CNC machining centers, ensuring the sharpness and accuracy of the tool edges.

- Used for grinding optical lens molds to ensure that the mold surface meets high-precision smoothness requirements.

- Processing metal materials, chip removal grooves help to remove metal shavings generated during the grinding process.

- When forming and grinding titanium alloy parts, the chip groove can prevent the accumulation of grinding chips, effectively avoiding grinding defects such as burns and cracks in titanium alloy parts.

Competitive Advantage

- To avoid chip accumulation and effectively prevent the accumulation of grinding chips between the grinding wheel and the workpiece.

- Improving machining accuracy can reduce the secondary wear of the machined surface caused by debris.

- Reduced the heat generated during the grinding process and minimized workpiece burns.

- Reduce the possibility of wheel blockage and improve processing efficiency.