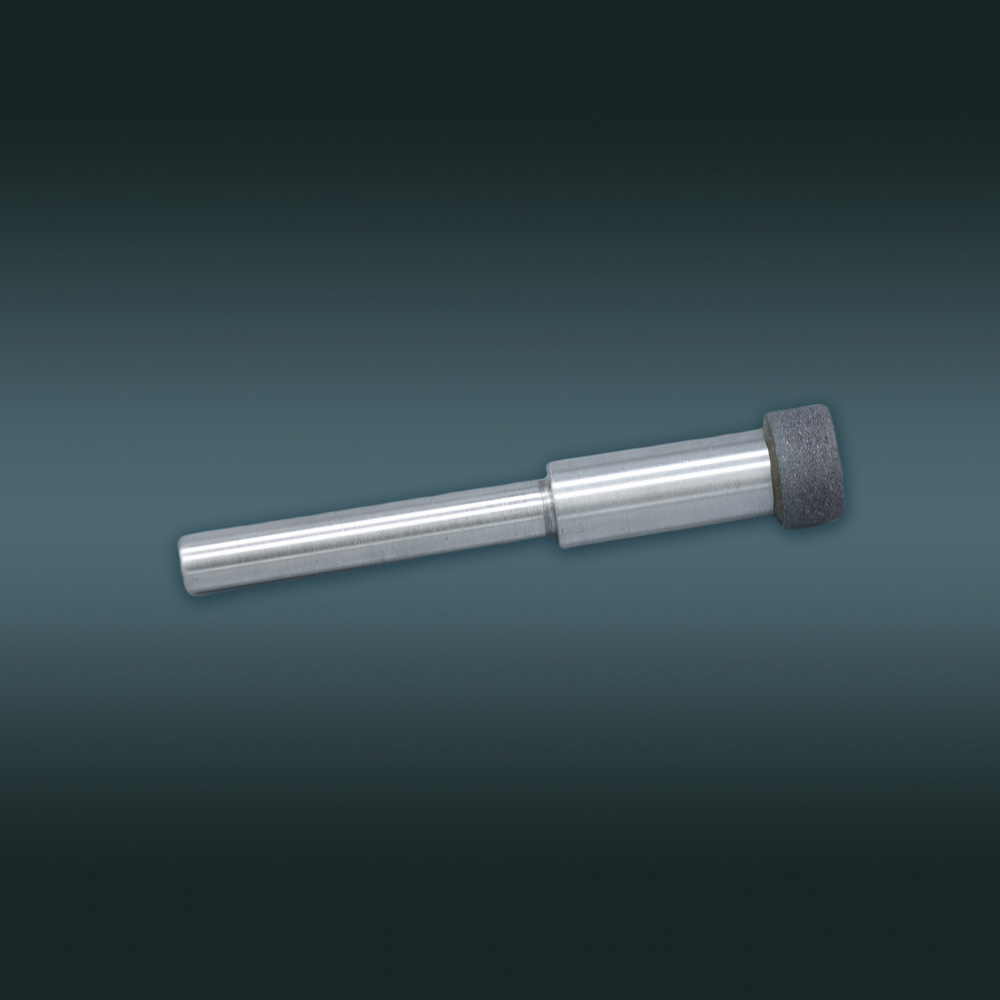

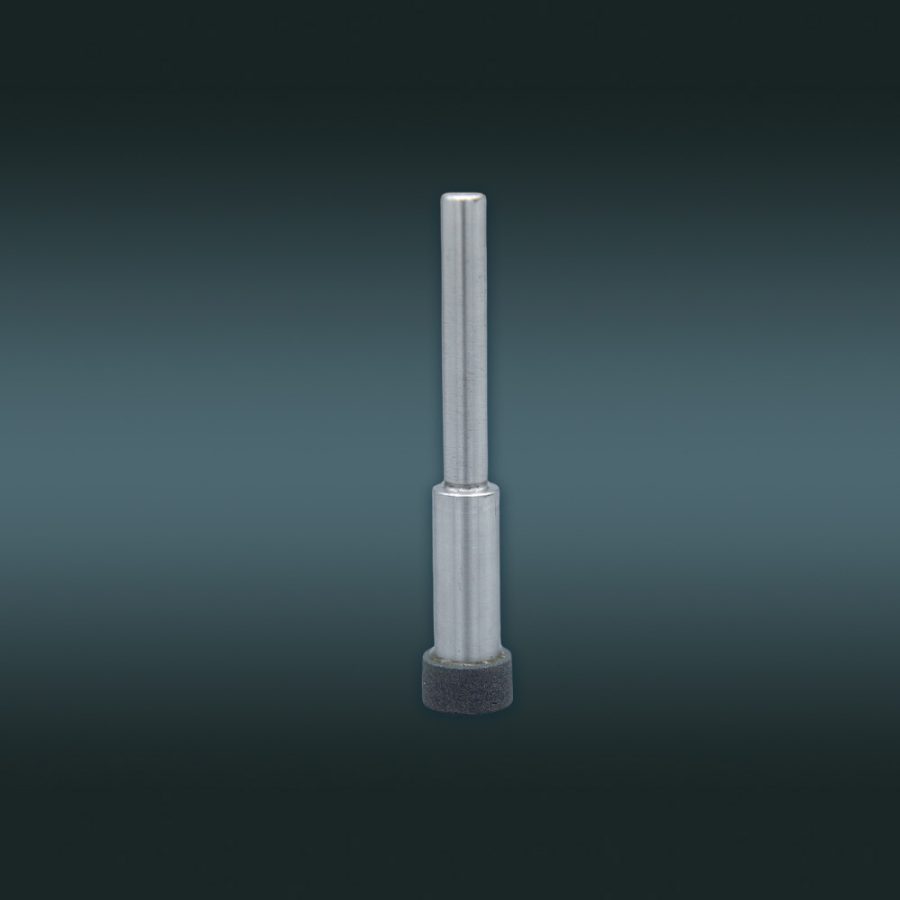

Vitrified CBN Grinding Head

-

Used for grinding high-speed steel, hard alloys, ceramics, etc., suitable for the automotive, bearing, compressor, aerospace fields.

High hardness, good wear resistance, good thermal stability, and high chemical stability.

Minimum Order Quantity: 50pcs

Net Weight: 30g

Payment: 30% advance

- Whatspp:+86 13357928197

- E-mail:wang@jyxhzs.com

Detail

Description

Vitrified CBN grinding heads have strong wear resistance, abrasive particles are not easy to fall off, good thermal stability, and is not prone to heating and blockage during grinding. It has a small thermal expansion and can effectively control machining accuracy, making it suitable for high-speed grinding and high-precision machining.

Specifications

| Place of Origin | China |

| Brand Name | Jiangsu Xingzuan Superhard Material Technology Co., Ltd |

| Certification | CNIPA |

| Abrasive | Diamond |

| Bond | Vitrified bond |

| Abrasive Grit Size | 80# |

| Model Number | DW |

| Length | 55mm |

| Net Weight | 30g |

| Minimum Order Quantity | 50pcs |

| Delivery Time | 30 days from advance payment |

| Supply Ability | Support customization |

| Payment | 30% advance |

Applications

- Used for grinding components such as crankshafts, camshafts, pistons, and cylinder blocks in automotive engines.

- Used for grinding inner and outer rings, rollers, etc. of bearings.

- Used for grinding various mechanical parts, such as machine tool guides, screws, gears, molds, etc.

- Used for grinding blades, turbine discs, shaft components, etc. of aircraft engines.

- Used for grinding various cutting tools, such as high-speed steel cutting tools, hard alloy cutting tools, ceramic cutting tools, etc.

Competitive Advantage

- High hardness, good wear resistance, abrasive particles are not easy to fall off, and can maintain sharpness for a long time.

- Excellent grinding performance, capable of achieving high-precision and high-efficiency grinding.

- Good thermal stability, less prone to heating and blockage, small thermal expansion, and effective control of machining accuracy.

- High chemical stability, not easily reacting with the processed material, ensuring the stability of the grinding process and the quality of the workpiece.