What do you know about Electroplated Diamond Cutting Discs?

- Whatspp:+86 13357928197

- E-mail:wang@jyxhzs.com

Detail

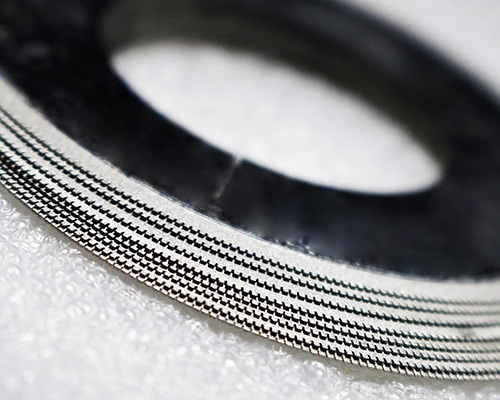

This electroplated diamond cutting blade is made of top-quality diamond material and refined through precision electroplating technology. It has excellent cutting performance and unparalleled hardness and precision and can be widely used in cutting stainless steel, glass tubes, and other hard materials.

1、 Characteristics of electroplated diamond cutting blades

Electroplated diamond cutting blades have high hardness and wear resistance. Diamond, as one of the hardest substances in nature, endows cutting blades with extremely high hardness and wear resistance, enabling them to easily handle cutting tasks of various hard materials.

Electroplated diamond cutting blades have high cutting efficiency. The electroplating process firmly adheres the diamond abrasive to the substrate, forming sharp cutting edges to ensure an efficient and stable cutting process.

Electroplated diamond cutting blades have a long service life. Due to the high wear resistance of diamonds and the strong combination of electroplating technology, the service life of electroplated diamond cutting blades is usually longer, which can reduce the frequency of replacement and lower the cost of use.

Electroplated diamond cutting blades have a wide range of applications, suitable for cutting various materials such as glass, ceramics, stone, alloys, etc. They are widely used in industries such as construction, automotive, electronics, jewelry, etc.

2、 Application fields of electroplated diamond cutting blades

Electroplated diamond cutting blades are applied in the construction field, and are favored for their efficient and precise cutting performance in processes such as glass curtain wall installation and tile cutting.

Electroplated diamond cutting blades are applied in automobile manufacturing. During the automobile manufacturing process, electroplated diamond cutting blades can be used to cut hard materials such as brake pads and engine components, improving production efficiency and product quality.

Electroplated diamond cutting blades are applied in the electronics industry. In precision machining fields such as semiconductors and optical glass, electroplated diamond cutting blades can ensure the smoothness and accuracy of the machined surface, meeting the requirements of high-precision machining.

Electroplated diamond cutting blades are used for jewelry processing. During jewelry processing, electroplated diamond cutting blades can be used to cut precious materials such as diamonds and gemstones, achieving fine processing and creative design.

3、 Precautions for the selection and use of electroplated diamond cutting blades

The hardness, toughness, and other characteristics of different materials vary, and it is necessary to choose a suitable electroplated diamond cutting piece.

When paying attention to cutting accuracy, for situations that require high-precision machining, electroplated diamond cutting blades with higher accuracy should be selected.

When using electroplated diamond cutting blades, safety operating procedures should be followed, protective equipment should be worn to ensure personal safety.

Regularly inspect and maintain electroplated diamond cutting blades to maintain their good working condition and cutting performance.